- Produktinfo

- Produktanmeldelser (0)

Produktinfo

Bestillingsvare. Ta kontakt for konfigurasjon og pristilbud.

Quantor MCK

The water chiller MCK consists of a cooling unit in the upper part and a pump plus isolated water tank (made of stainless steel) in the lower section. The unit is conveniently constructed from a frame with removable side panels, allowing easy access to the inner components. The ventilator is assembled at the top part of the unit blowing the warm air upwards.

The new generation of MCK units is equipped with high efficiency micro-channel condenser which allows for a very compact framework. The unit models 50 -181 are mobile on wheels. The larger units are standing on four corner-feet in standard. Wheels for large units are provided as option. All MCK units are equipped with an electric heating rod. The MCK functions fully automatically andrequiresnosupervision.

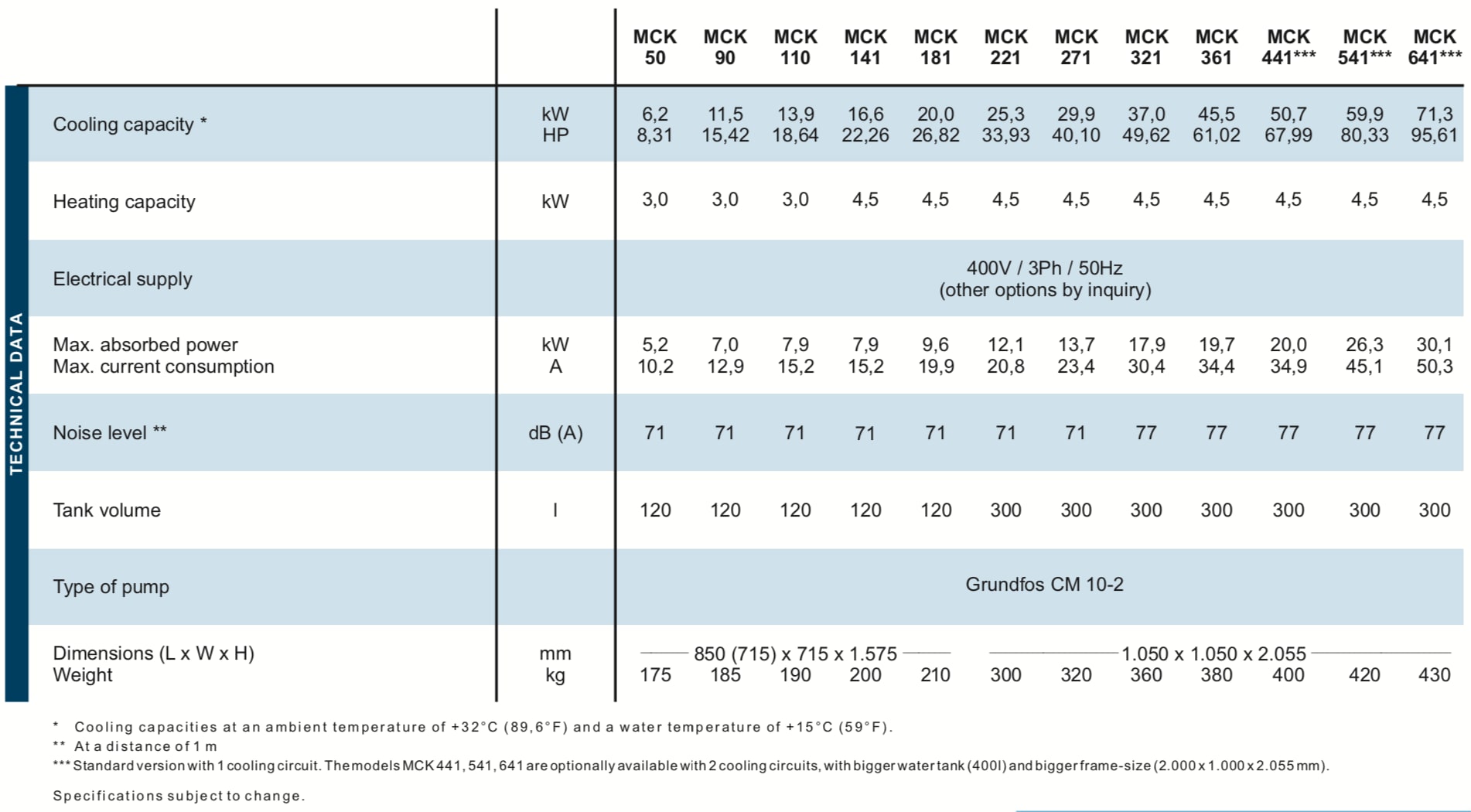

The cooling and heating units MCK are available in twelve different models, the range of performance is between 6,2 and 71,3 kW. Larger units with higher capacity up to 285kW and units with different voltage levels can be built to order.

CHARACTERISTICS

- Hermetically closed motor compressor (Scroll)

- Complete cooling water circuit with highly efficient micro- channel condenser, insulated stainless steel water tank, centrifugal pump and electric heating rod

- Pressure switch integrated in the cooling circuit for pump control - pump protection and energy-saving

- Integrated level-switch and integrated by-pass for pump protection and tank circulation

- All water parts in the unit are isolated

- Stainless steel frame with painted front board

- MCK 50 - 181 mobile on wheels (in standard); wheels for larger units possible as option

- Easy access to the inner components due to easy removable side-boards

- Ventilator on the top part, air-blow direction upwards·Refrigerant R410A

- Protection type of the chiller is IP54 minimum

- It is required to add Glycol (30 - 35%) to the cooling water by outlet temperatures below +7°C.

- Cooling and heating of must, wine, beer and other liquids such as cider, carbonated soft-drinks, distillates etc.

- Fermentation temperature control

- Tartaric stabilisation of wines and biological reduction of acids

- Cool storage of wine until bottling

- Maturation of young beer

- Cooling and stabilisation of distillates

- Room temperating of halls and storage rooms - only possible with additional fan coils

Skriv en produktanmeldelse og del dine erfaringer med dette produktet med andre kunder.